Core Technology

Ultra HD Video

Smart Manufacturing

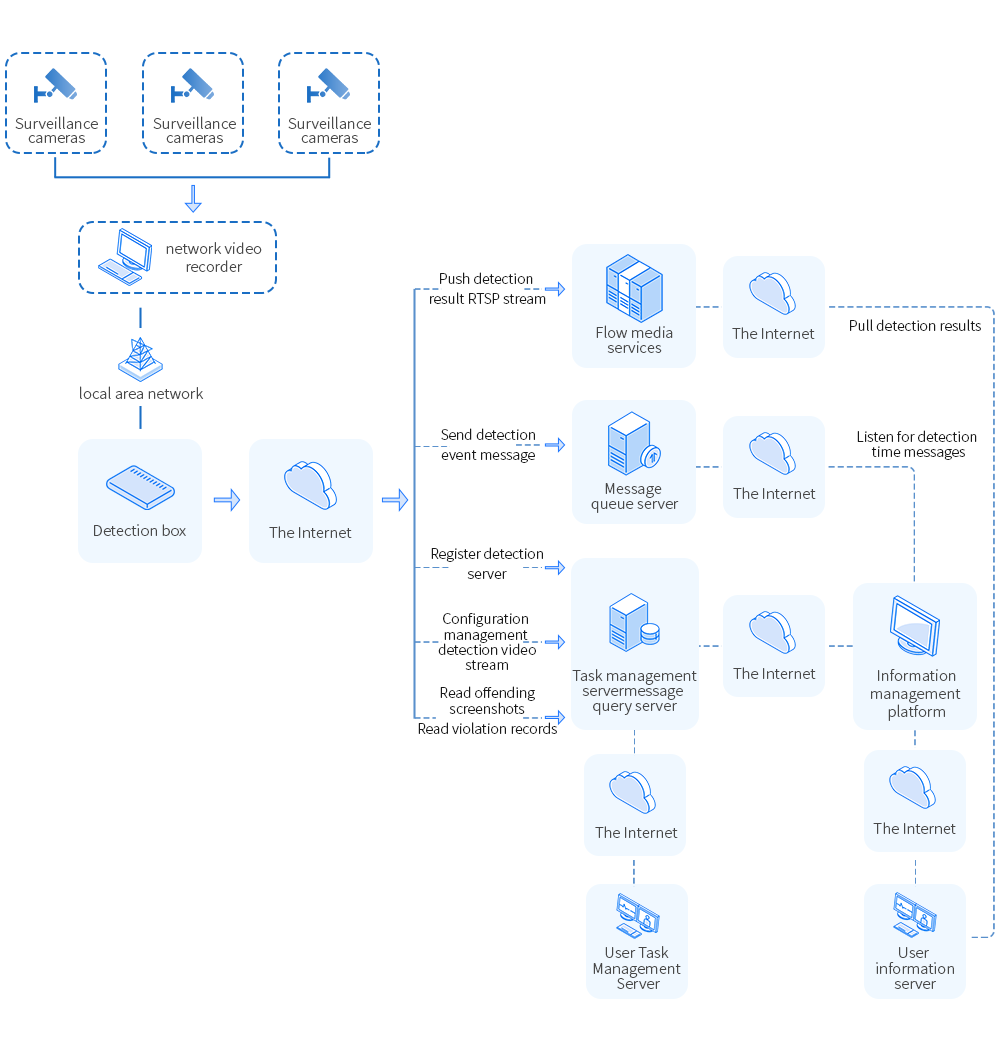

IVCloud

Retouching APP

About

.png)